Description

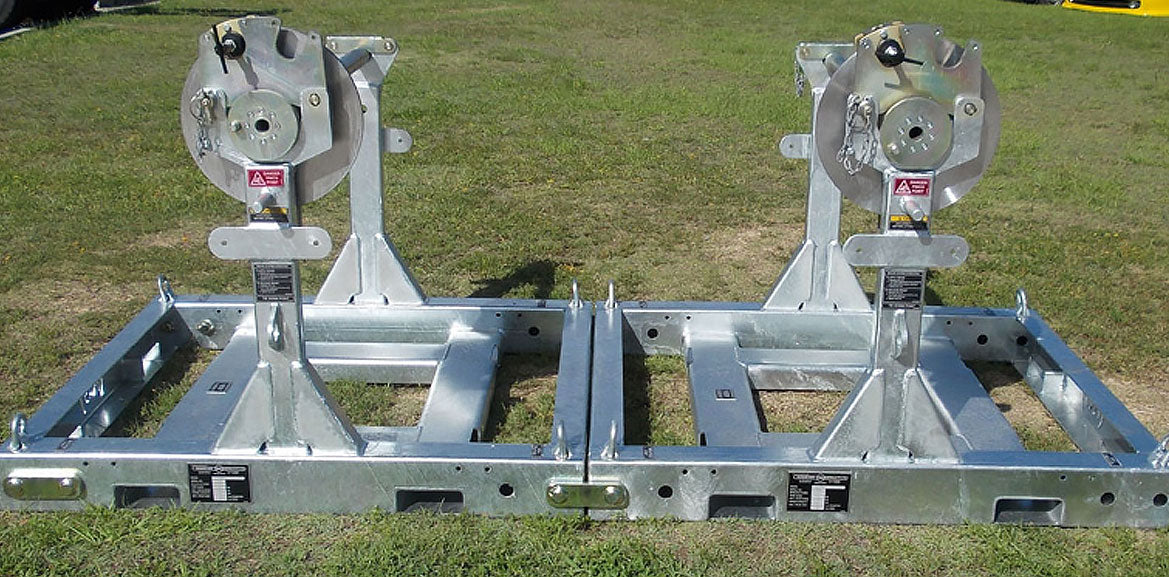

These robust hot dip galvanized cable drum stands are designed to be placed on the ground or on the back of a tray-back truck and are provided with container lock mounting points. All spindle hardware is zinc plated and gold passivated, the hydraulic disc brake is manufactured from stainless steel and the power pack enclosure is powdercoated. They are also provided with lifting lugs, one on each corner. In addition to this, there are lifting points provided on each end of the spindle assembly for lifting the drum and spindle out of the stand. The spindle is manufactured from special high tensile hollow section and can be lifted by one person.

10 Tonne skid-mount cable drum stand complete with a line brake (pay out) capacity of 200kg at 1000mm diameter. As an optional extra, these drum stands may be supplied with an integrated diesel/hydraulic power unit and drum drive with a line pull (recovery) capacity of 500kg at 1000mm diameter.

Specification

Maximum Drum Mass: 10,000kg

Maximum Drum Diameter: 2800mm

Maximum Drum Width : 1500mm

Spindle diameter: 95mm

Please note the spindle diameter quoted is a special lightweight spindle with 95mm outside diameter. If 90mm is required, this will be a solid spindle in order to carry the 6 tonne drum weight. A solid spindle will be much heavier than the hollow one we normally provide and it will be a 2 or 3 man operation to lift the spindle. For this reason, most authorities prefer lightweight spindles.

Options

Option 1

Single 10 Tonne drum stand assembly

Including

– Stainless steel disc brake assembly, 200 kg tension.

– 95mm spindle assembly,

– Integral diesel/hydraulic power pack and valving

– 500 kg line pull drum rotator assembly.

(view image)

Option 2

Single 10 Tonne drum stand assembly

Including

– Stainless steel disc brake assembly, 200 kg tension.

– 95mm spindle assembly,

– Integral /diesel/hydraulic power pack and valving

– 500 kg line pull drum rotator assembly.

– Fairlead control system.

Excluding

– Fairlead framework and mechanismSuitable for use with intermediate frame and fairlead system as per option 8.

Excluding

– Diesel/hydraulic power pack

(view image)

Option 3

Single 10 Tonne drum stand assembly

Including

– Stainless steel disc brake assembly, 200 kg tension.

– 95mm spindle assembly,

– 500 kg line pull drum rotator assembly.

– Hydraulic control valvingExcluding

– Diesel/hydraulic power packSuitable for use with truck PTO drive or remote diesel/hydraulic power unit as per Option 5.

(view image)

Option 4

Manufacture remote skid mounted diesel/hydraulic power unit suitable to drive ONE Single 10 Tonne drum stand assembly. Typically as per option 4.

– Excludes hydraulic control valving

– Includes hose reels

(view image)

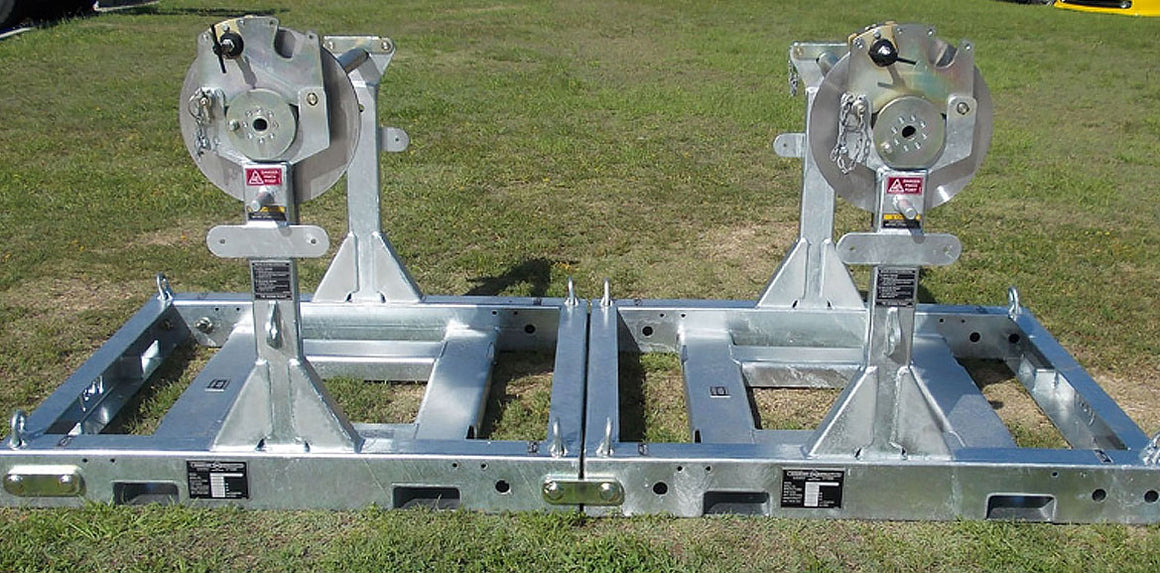

Option 5

Manufacture one intermediate subframe to support TWO non powered drum stands Typically option 1.

(Excluding drum stands )

Option 6

Manufacture one intermediate subframe to support TWO powered drum stands. Typically supporting one unit as per option 3 and one unit as per option 4.

(Excluding drum stands)

Option 7

Manufacture one intermediate subframe to support TWO powered drum stands complete with fairlead assembly. Typically one unit as per option 3 and one unit as per option 4.

(Excluding drum stands)

Option 8

Manufacture one intermediate subframe to support THREE non powered drum stands. Typically three units as per option 1. (Excluding drum stands)

(view image)

Option 9

Manufacture heavy-duty overhead support roller. Maximum cable capacity 100mm diameter.

Option 10

Manufacture light duty overhead support roller. Maximum cable capacity 40mm diameter.

Option 11

Spreader bar and chain assembly for lifting drums in and out of stand

Option 12

Additional 3000 kg spindle

Option 13

Complete 3000 kg spindle and brake assembly

Option 14

Hydraulic hand-pump assembly for greater brake control.

Option 15

1000 kg line pull drum rotator assembly.

Option 16

Upgrade stainless steel brake spindle assembly from 200 kg tension to 900 kg tension

(view image)

Option 17

Upgrade 500 kg line pull (rotator) to 1000 kg line pull.

Option 18

Intermediate Frame Lifting Attachment

(view image)

Option 19

3mm Aluminium checker plate flooring put on the base of Drum Stands – Options 1, 2, 3 and 4

(view image)

Option 20

Set of fold-down decking and suitable barrier system to suit 3-Drum intermediate stand – Option No. 9

(view image)

Option 21

3mm checker plate flooring for 3-Drum intermediate stand – Option No. 9

Option 22

Forklift tyne apertures

(view image)